The Artistry of Woodworking Joints

Woodworking joints are at the heart of fine craftsmanship, combining function and beauty to create lasting structures and pieces. As a master wood craftsman, I often use various joint techniques to design unique home decor products and furniture that are both visually appealing and structurally sound. In this post, we'll explore the fundamentals of woodworking joints, their types, purposes, and even dive into the cultural differences between Western and Japanese joinery. We'll also discuss how joinery can influence design, cost, and structural decisions.

What Is a Woodworking Joint?

A woodworking joint is the point where two pieces of wood connect, often through precise cuts or interlocking shapes, to create a secure bond. These joints are essential in both construction and furniture making, ensuring stability without relying solely on glue or fasteners.

The Function of Woodworking Joints

The fundamental role of a joint is to accomplish several critical tasks, such as:

Provide structural stability

Adapt to shifts in size caused by variations in temperature and humidity

Enhance aesthetics with seamless or decorative connections

Woodworking joints are more than just connections—they're a testament to the skill of the craftsman and the design integrity of the piece.

Why Joints Matter

Beyond function, joints offer flexibility in design. Proper joinery allows for modular construction, enabling pieces to be disassembled and reassembled. This can be crucial for repairs or modifications over time. Additionally, the appearance of a well-crafted joint can elevate a piece, showcasing the artisan's attention to detail and mastery of technique.

Types of Woodworking Joints

Woodworking joints come in various shapes and styles, each suited to specific applications. Below, we'll break down the most common types:

1. Butt Joint

Definition: The simplest type of joint where two pieces of wood meet at a right angle.

Simple Butt Joint

Wood joined together at a right angle

Uses: Often used in basic framing or utility projects.

Pros:

Easy to construct

Requires minimal tools

Cons:

Weak unless reinforced with glue, screws, or nails

Not ideal as a stand-alone joint in load-bearing structures.

Tips for Strengthening Butt Joints: Adding dowels or biscuits can help reinforce the joint. Using pocket-hole screws also improves strength without compromising appearance.

Design Enhancements: Butt joints can be improved aesthetically with edge banding or veneer coverings, giving them a cleaner finish when exposed.

2. Miter Joint

Definition: Similar to a butt joint, but the ends are cut at angles of degree to suit the desited shape.

Miter Joint

Common 45° Miter Joint

Uses: Perfect for picture frames, decorative trims, and angled corners.

Pros:

Clean, professional appearance

No visible end grain

Cons:

Requires precise cutting for accuracy

Needs reinforcement for strength

Miter Joint with Spline

Splines strengthen the joint by adding side grain to the joint - providing more surface area for glue

Pro Tip: Reinforce miter joints with splines or other fasteners for added durability while maintaining visual appeal.

Challenges and Variations: Miter joints can be delicate and prone to opening if not perfectly aligned. Variations, such as adding corner blocks or using lock miters, can significantly improve strength and reliability.

3. Dovetail Joint

Definition: An interlocking joint made by cutting wedge-shaped “tails” and “pins” that fit together perfectly.

Uses: Ideal for drawers, boxes, and high-end furniture.

Dovetail Joint

The interlocking tails and pins are fit together make the joint both durable and beautiful

Pros:

Extremely strong and durable

Highly decorative

Cons:

Time-consuming and requires skill to create

Variations:

Through Dovetail: Visible from both sides, often used decoratively.

Half-Blind Dovetail: Hidden on one side, ideal for drawers.

Historical Significance: Dovetail joints have been used for centuries and are often seen in antique furniture, symbolizing high-quality craftsmanship.

4. Dado Joint

Definition: A groove cut into one piece of wood to accept the edge of another piece.

Dado Joint

The dado joint is commonly used in bookshelves, and can be Both decorative (as shown left) and functional joint.

Uses: Frequently used in shelving, cabinetry, and bookcases.

Pros:

Strong and versatile

Simple to create with the right tools

Cons:

Visible joints may detract from appearance

Advanced Tip: Use stopped dado cuts to hide the joint ends for a cleaner appearance.

Modern Applications: With the rise of modular furniture, dado joints remain a staple due to their ability to combine strength and quick assembly, often paired with adhesives for added stability.

Why Not Use Fasteners?

While screws, nails, and glue can be used to hold wood pieces together, they lack the strength and durability that interlocking joints provide. Fasteners can weaken over time due to movement, moisture, or structural stress, whereas joints are designed to distribute weight and stress more evenly. Additionally, joints contribute to the aesthetics, offering seamless transitions that fasteners cannot achieve.

The Limitations of Fasteners

Movement Over Time: Fasteners loosen due to wood expansion and contraction.

Appearance: Visible screws or nails can detract from craftsmanship.

Durability: Joints provide mechanical strength, whereas fasteners rely on adhesion or compression.

What Is Western Joinery?

Western joinery has developed through centuries of practical woodworking and architectural needs, emphasizing functionality, efficiency, and adaptability. Unlike Japanese joinery, which often avoids fasteners, Western joinery frequently integrates nails, screws, and adhesives to reinforce strength and simplify construction.

History and Evolution

Western joinery traces its roots to medieval European timber framing and furniture making. Early techniques evolved alongside tool advancements, moving from hand tools to power tools, which allowed for faster and more repeatable cuts. The Industrial Revolution further influenced Western joinery, emphasizing mass production and accessibility.

Techniques and Design Philosophy

Western joints prioritize practicality and ease of construction while still allowing for decorative elements. Techniques such as dovetails and mortise-and-tenon joints are prized for their strength, while modern tools enable highly precise cuts for repeatable patterns in mass production.

Learning and Application

Western woodworking is widely taught through trade schools and workshops, offering structured programs focused on precision and efficiency. It’s often more approachable for

beginners due to the reliance on power tools and jigs that simplify the process.

What Is Japanese Joinery?

Japanese joinery has captivated woodworkers around the world due to its beauty, precision, and ability to harness wood’s natural strength. Rooted in centuries of tradition, this form of woodworking avoids nails and screws, relying instead on carefully designed interlocking joints.

History and Philosophy of Japanese Joinery

Japanese joinery dates back over a thousand years and was heavily influenced by Buddhist temple construction. Carpenters created intricate joints to withstand earthquakes and other natural forces, emphasizing resilience and harmony with nature.

The philosophy behind Japanese joinery centers on balance, simplicity, and respect for materials. Each joint is designed to complement the natural grain and strength of the wood, ensuring durability and visual appeal.

Techniques for Design, Function, and Beauty

Japanese joints often feature complex, puzzle-like designs. Examples include:

Kigumi: Intricate patterns that interlock without adhesives.

Kanawa Tsugi: Scarf joints used to extend beams.

Shachi-Sen: Wedge-shaped joints for added strength.

These joints are functional but also decorative, showcasing the artisan’s skill and attention to detail.

Learning Curve and Precision Craftsmanship

Mastering Japanese joinery requires years of training and practice. Craftsmen must develop precision cutting skills, often using hand tools like chisels and saws to create flawless joints. Apprenticeships in Japan often last several years, emphasizing patience and discipline.

Western vs. Japanese Joinery

Western Joinery

Western Scarf Joint

Efficient and Functional method to extend the length of wood; with glue

Western woodworking joints prioritize efficiency and functionality. Many designs focus on speed and repeatability, making them ideal for mass production.

Japanese Joinery

Japanese Scarf Joint

Precise cuts used to lengthen wood without glue

Japanese joinery, on the other hand, emphasizes precision, artistry, and longevity. Traditional Japanese joints often avoid nails or screws entirely, relying solely on the wood's natural strength.

Key Similarities and Differences

Similarities: Both styles emphasize structural integrity and aesthetics.

Differences: Western joinery often favors glue and screws, while Japanese joinery relies heavily on intricate cuts and interlocking designs.

Image Suggestion: Side-by-side examples of Western and Japanese joints.

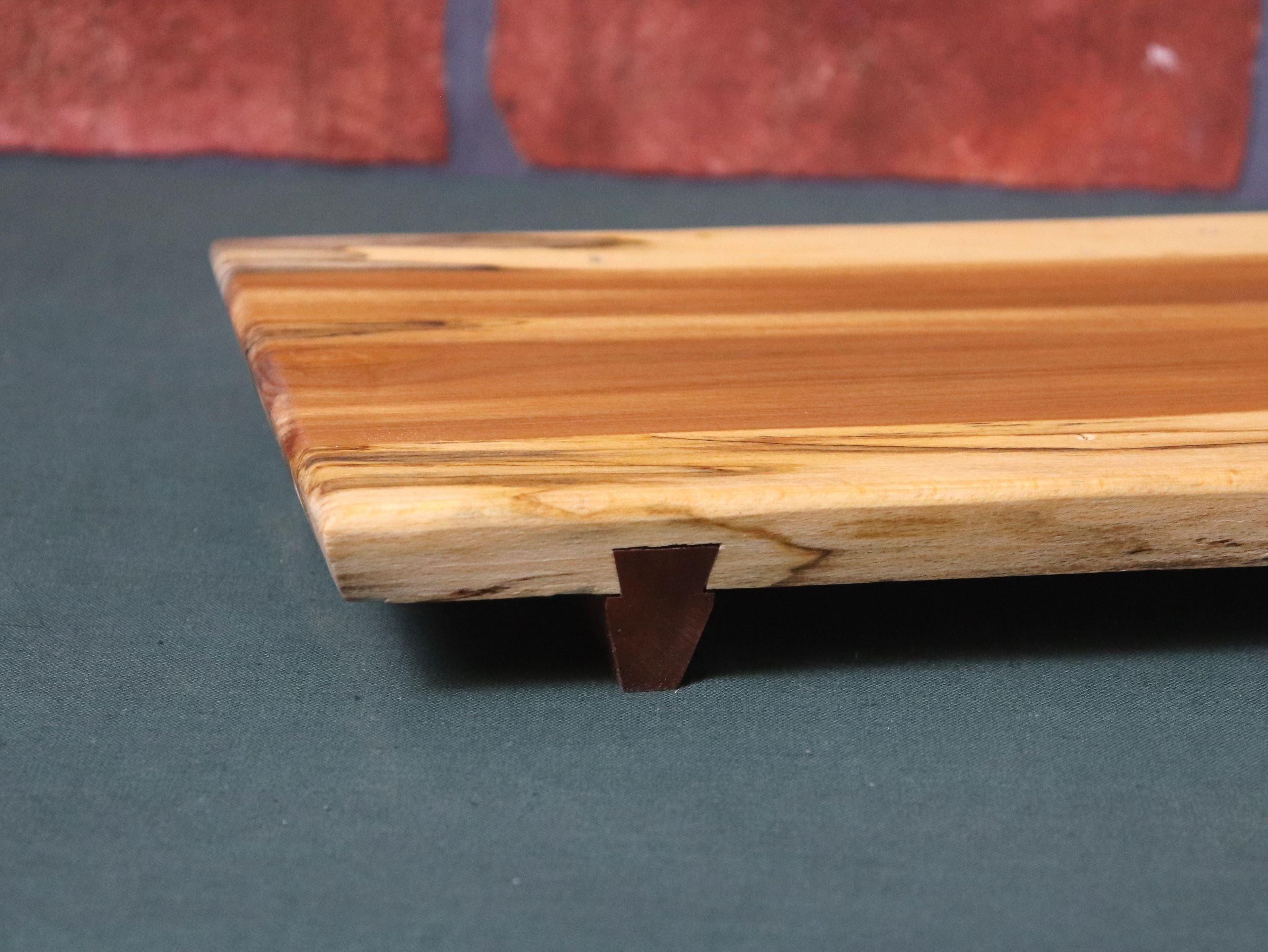

Joinery as a Design Element

Joinery isn’t just about function—it plays a pivotal role in aesthetics. Decorative joints, such as dovetails and box joints, can turn utilitarian structures into works of art.

Visual Appeal and Craftsmanship

Intricate joints often highlight the skill and artistry of the craftsman. Visible joinery can enhance the visual appeal of furniture, acting as both a focal point and a testament to precision. For example, exposed dovetails in drawers or butterfly keys in tabletops make strong statements about quality and attention to detail.

Combining Form and Function

Joinery blends structure and beauty, offering designs that are not only stable but also visually interesting. This approach is often seen in high-end furniture, where joints are left exposed to emphasize craftsmanship.

Modern Trends in Decorative Joinery

In contemporary designs, woodworkers increasingly use contrasting woods to highlight joints, adding visual intrigue. Patterns created by finger joints or through-tenon connections add layers of detail that complement modern and rustic styles alike.

Image Suggestion: Close-up of exposed dovetail or butterfly joints to showcase decorative craftsmanship.

Woodworking joints combine strength, beauty, and functionality. Stay tuned for more insights into woodworking techniques and tips in future blog posts!

Visit Grayhill Woodworking LLC to explore our collection of unique, artisan pieces.